Renewable Design for boom lift platform - Manufacturers supply gear pump automation machinery hardware hydraulic gear pump – Tend

Renewable Design for boom lift platform - Manufacturers supply gear pump automation machinery hardware hydraulic gear pump – Tend Detail:

Product Description

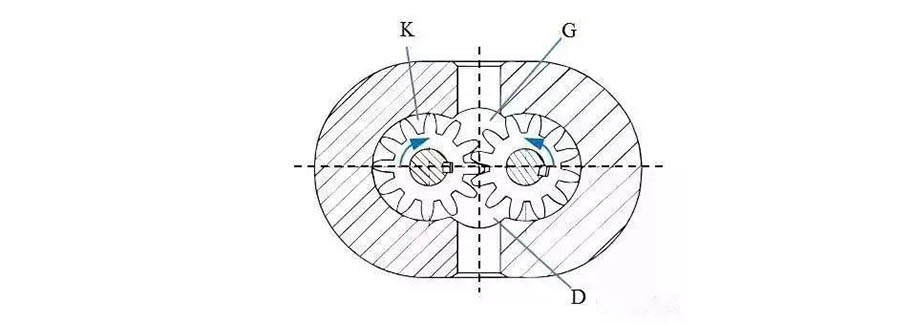

The tooth top cylinder and the end faces on both sides of a pair of gears meshing with each other are close to the inner wall of the pump casing, and a series of sealed working cavities K are enclosed between each tooth slot and the inner wall of the casing. The D and G cavities separated by the meshing gear teeth are the suction chamber and the discharge chamber communicated with the suction port and the discharge port of the pump, respectively. As shown (external meshing).

When the gear rotates in the direction shown in the figure, the volume of the suction chamber D gradually increases and the pressure decreases due to the meshing gear teeth gradually exiting the meshing state. Under the action of the pressure difference between the liquid surface pressure of the suction pool and the low pressure in cavity D, the liquid enters the suction chamber D from the suction pool through the suction pipe and the suction port of the pump. Then it enters the closed working space K, and is brought to the discharge chamber G by the rotation of the gear. Because the teeth of the two gears gradually enter the meshing state from the upper side, the teeth of one gear gradually occupy the cogging space of the other gear, so that the volume of the discharge chamber located on the upper side gradually decreases, and the liquid pressure in the chamber increases, so the pump is discharged from the pump. The discharge port is discharged out of the pump. The gear rotates continuously, and the above-mentioned suction and discharge processes are carried out continuously.

The most basic form of the gear pump is that two gears of the same size mesh and rotate with each other in a tightly fitted casing. The inside of the casing is similar to the “8″ shape, and the two gears are installed inside. The housing is a tight fit. The material from the extruder enters the middle of the two gears at the suction port, fills the space, moves along the casing with the rotation of the teeth, and finally discharges when the two teeth mesh.

Features

1. Good self-priming performance.

2. The direction of suction and discharge depends entirely on the direction of rotation of the pump shaft.

3. The flow rate of the pump is not large and continuous, but there is pulsation and the noise is large; the pulsation rate is 11%~27%, and its unevenness is related to the number and shape of gear teeth. The unevenness of helical gears is smaller than that of spur gears, and the human The unevenness of the helical gear is smaller than that of the helical gear, and the smaller the number of teeth, the greater the pulsation rate.

4. The theoretical flow is determined by the size and speed of the working parts, and has nothing to do with the discharge pressure; the discharge pressure is related to the pressure of the load.

5. Simple structure, low price, few wearing parts (no need to set suction and discharge valve), impact resistance, reliable operation, and can be directly connected with the motor (no need to set a reduction device).

6. There are many friction surfaces, so it is not suitable to discharge liquids containing solid particles, but to discharge oil.

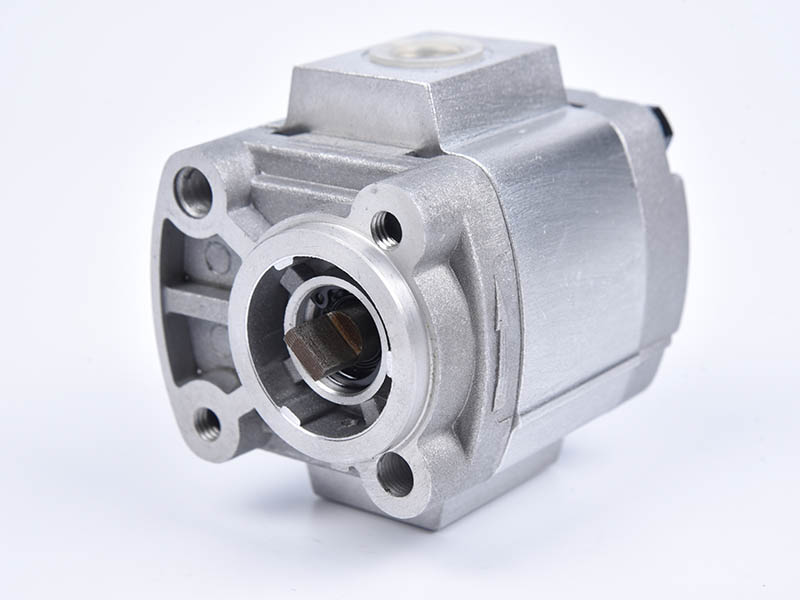

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Renewable Design for boom lift platform - Manufacturers supply gear pump automation machinery hardware hydraulic gear pump – Tend , The product will supply to all over the world, such as: Ecuador, Tunisia, Cyprus, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We will not live up to the historic opportunity of the times.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.