Forklift fully automatic scissor-type self-propelled hydraulic lift all-electric aerial work platform

Product Description

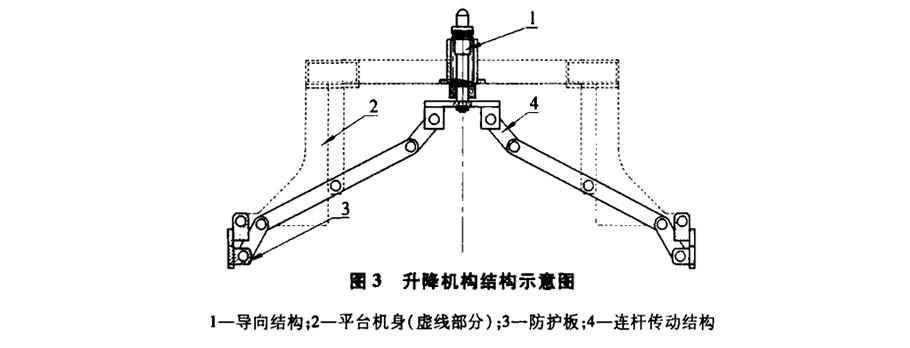

Self-propelled scissor aerial work platform has many functions such as lifting of engineering components, manned aerial work, and lifting of equipment and materials. It is mainly used in the decoration and maintenance of steel structure workshops, exhibition halls and other buildings and aircraft Maintenance of large equipment, etc. The application of self-propelled scissor aerial work platform can improve the efficiency of climbing work, improve the working environment at heights, and reduce accidents at work at heights. The scissor-type aerial work platform of Yunxiang Heavy Industry is equipped with a protective plate elevator pothole protection mechanism, a rod-type linkage lifting mechanism, which includes two parts: a guide structure and a connecting rod transmission structure.

The protective plate lifting mechanism is a necessary safety device to protect workers when working at heights. Yunxiang Heavy Industry's self-propelled scissor aerial work platform protection plate lifting mechanism is a link-type protection plate lifting mechanism, which is linked with the scissor arm and the platform. When the platform height rises to a dangerous height, the protection on both sides The board is fully opened, and the ground clearance of the double-sided protective board is less than 10mm. Successfully protected the car from overturning accidents that may be caused by the collapse of the ground.

The self-propelled scissor-type aerial work platform consists of a lifting mechanism and a self-propelled carrying chassis. In the process of engineering operation, the staff on the work platform can simultaneously operate the lifting mechanism and the carrying chassis and operate continuously, which avoids wasting time due to the frequent change of the work place. In order to ensure the safety of personnel in the platform when working at heights, it is required that when the working platform is raised, the working platform cannot travel on the road with large slopes or bumps.

When the scissor arm is lifted, the self-propelled scissor aerial work platform opens the protective plate mechanisms on both sides of the chassis to reduce the height of the platform chassis, so that the movement of the platform is limited to play a protective role. For this reason, the protective plate lifting mechanism linked with the scissor arm of the aerial work platform enables the protective plate to be retracted when the scissor arm is retracted, and the moving mechanism can travel normally. It is opened to limit the travel of the work platform on the road with steeper slopes or bumps.

In order not to increase the number of driving elements in the working platform and the difficulty of platform control, the protective plate lifting mechanism designed by the imagined scissors forklift is driven by the lifting of the scissor arm, that is, when the scissor arm is retracted, the protective plate mechanism drives the protective plate to retract, and the scissors fork lifts. When the arm is raised, the protective plate lifting mechanism drives the protective plate to open, which is both safe and efficient.

Certificate

Certificate: ISO and CE Our services:

1. Once we understand your requirements, we will recommend the most suitable model to you.

2. Shipment from our port to your destination port can be arranged.

3. Opetion video can be sent to you if you want.

4. When the automatic scissor lift fails, a maintenance video will be provided to help you repair it.

5. If needed, the parts for automatic scissor lift can be sent to you by express within 7 days.

FAQ

1. If the parts are broken, how can customers buy them?

Automatic scissor lifts use most of the commonly used hardware. You can buy these parts at your local hardware market.

2. How does the customer repair the automatic scissor lift?

A great advantage of this device is that the failure rate is very low. Even in the event of a breakdown, we can guide repairs with videos and repair instructions.

3. How long is the quality guarantee?

One year quality guarantee. If it fails within one year, we can ship the parts to you free of charge.